Concrete Plant Costs

How Market Conditions Are Shaping Concrete Plant Cost in the Construction Industry

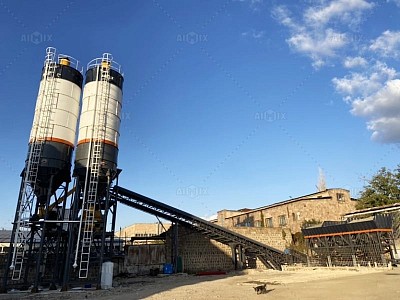

In today’s ever-evolving construction industry, understanding the concrete plant cost is crucial for contractors, developers, and project managers alike. The price of a concrete plant is no longer determined by equipment alone. Instead, it reflects a complex mix of market forces, global supply chains, regional demand, and technological advancements. As the need for faster, higher-quality construction grows, so too does the attention on choosing the right types of concrete batching plant at the best cost-performance ratio.

Concrete Plant Cost: More Than Just the Price Tag

When people talk about concrete plant cost, they often refer to the initial investment. However, the total cost includes much more:

Initial purchase price

Installation and commissioning

Transport and logistics

Maintenance and spare parts

Operational costs (power, water, labor)

Downtime and productivity loss if not well-matched to project demands

Depending on the type of concrete batching plant and its capacity, the cost can range from $25,000 for small mobile plants to over $300,000 for large, fully automated stationary setups.

Key Market Factors Influencing Concrete Plant Cost

1. Raw Material and Steel Prices

Steel is a core component of batching plant frames, silos, conveyors, and mixer drums. Global fluctuations in steel prices—caused by supply chain disruptions, geopolitical tensions, or trade policies—directly impact concrete plant cost. Since 2021, many manufacturers have adjusted prices to accommodate rising material costs.

2. Labor and Production Costs in Manufacturing Countries

Plants manufactured in countries with lower labor costs (e.g., China, India, Turkey) generally offer competitive pricing. However, buyers must weigh this against shipping costs, import duties, and after-sales support availability.

3. Freight and Logistics Challenges

With container shortages and port delays still affecting global trade, freight can significantly increase the overall cost. For international buyers, especially in remote or landlocked areas, this adds a considerable layer to budgeting.

4. Technological Advancements

Modern plants come equipped with automated control systems, real-time monitoring, moisture sensors, and energy-efficient components. While this increases upfront costs, it improves productivity and reduces long-term operational expenses. The tech-driven trend is redefining the total cost-benefit analysis of concrete plant cost.

5. Demand and Construction Boom

In regions undergoing rapid infrastructure growth (like the Middle East, Southeast Asia, or Africa), high demand for concrete plants drives prices up. Limited supplier capacity in peak seasons also affects delivery times and pricing.

Types of Concrete Batching Plant: Cost Comparison

Choosing the right types of concrete batching plant plays a significant role in determining total project cost. Here’s a breakdown of the major types and their cost-related implications:

1. Stationary Batching Plant

Best for: Large-scale, long-term projects (e.g., highways, airports, dams)

Cost Range: $70,000 – $300,000+

Cost Drivers: Higher production capacity, complex foundations, longer installation times

2. Mobile Batching Plant

Best for: Projects requiring frequent relocation or remote job sites

Cost Range: $25,000 – $120,000

Cost Drivers: Compact design, portability, quick setup

3. Wet Mix Plant

Best for: High-strength concrete with strict quality standards

Cost Range: Medium to High

Cost Drivers: Twin-shaft mixers, water control systems, precision batching

4. Dry Mix Plant

Best for: Transit mix operations and remote areas with fewer infrastructure needs

Cost Range: Lower upfront cost

Cost Drivers: Simpler design, fewer components, relies on truck mixers

5. Precast Batching Plant

Best for: Manufacturing precast concrete components (walls, slabs, beams)

Cost Range: High

Cost Drivers: Custom molds, precise batch cycles, controlled environments

Balancing Cost vs. Value: What Developers Should Consider

While initial investment is important, focusing solely on price may lead to performance issues, frequent breakdowns, or inefficiencies. Instead, real value lies in:

Automation: Plants with PLC controls and digital monitoring help reduce manual labor and waste.

Scalability: Modular plants that can grow with your project are a better long-term investment.

Energy Efficiency: Look for systems with low power consumption and water recycling.

Warranty and Support: A slightly more expensive plant with strong after-sales service may save you thousands over its lifetime.

Regional Case Study: Concrete Plant Cost in the UAE

In regions like the UAE, where urbanization is booming, the demand for high-quality and efficient concrete plants is at its peak. Here, buyers prioritize:

Hot weather adaptations (cooling systems)

Fast mixing cycles for tight schedules

Compliance with local safety and environmental laws

The concrete plant cost in the UAE is generally higher than average due to higher import duties, quality expectations, and customization needs. Still, the ROI is strong thanks to the volume and pace of construction projects.

Conclusion: Smart Investment Starts with Market Awareness

Understanding how market conditions shape the concrete plant cost helps construction professionals make informed decisions. By assessing not just the price, but also the type, technology, and long-term value, developers can choose the right types of concrete batching plant for their project size, region, and future scalability.

Whether you’re building in Dubai, Manila, or Nairobi — selecting the right plant at the right time can save you money, time, and stress.